The Standard Process of Powder Coating for LED Light Housing Fixtures

Powder Coating Workshop for LED Light Housing

What is Powder Coating?

Powder coating is a dry finishing process that has become extremely popular since its introduction in North America over in the 1960s. Representing over 15% of the total industrial finishing market, powder is used on a wide array of products including in die-casting LED lighting fixtures. More and more companies specify powder coatings for a high-quality, durable finish, allowing for maximized production, improved efficiencies, and simplified environmental compliance. Used as functional (protective) and decorative finishes, powder coatings are available in an almost limitless range of colors and textures, and technological advancements have resulted in excellent performance properties. Normally Moonlight will choose the following colors for the LED light housings: Gray, Black, White, and Dark Bronze.

How Powder Coating Works?

The powder sticks to the die-casting parts of LED light housing fixtures due to electrostatic charging of the powder and grounding of the die-casting parts of LED light housings. The powder and that can be electrically grounded to enhance charged particle attachment. The powder flows and cures during the application of heat.

The Advantages and Disadvantages Comparing with Painting

Several advantages of powder coating over paints are:

- Powder recovery for reuse

- No VOC generation therefore no VOC destruction required

- Can be more durable than paints (powder chemistry dependent)

Several disadvantages of powder coating over paints are:

- Can have less leveling than paint (more orange peel)

- 2. Curing is typically more energy intensive than paint drying due to higher temperature requirements.

- 3. Surface preparation before powder coat application is still critical for adhesion and defect avoidance.

Typical Steps in a Powder Coating Process for Die-casting LED light Housing Fixtures:

- Cleaning (typically an alkaline cleaner for the substrate of aluminum alloy die-casting parts of LED light housings.)

- Rinsing the die-casting parts of LED lighting fixtures.

- Photostatting the die-casting parts of LED lighting fixtures.(Optional step to improve corrosion protection and adhesion)

- Drying the die-casting parts of LED lighting fixtures.

- Powder Coating the die-casting parts of LED lighting fixtures.

- Curing the die-casting parts of LED lighting fixtures. (Typically energy intensive since relatively high temperatures are required to get the powder to liquefy and flow)

After these process, the whole process of powder coating for LED lighting fixtures are ready. All of our die-casting LED floodlight housing, LED street light housing, LED high bay housings and LED wall pack housings are following these steps.

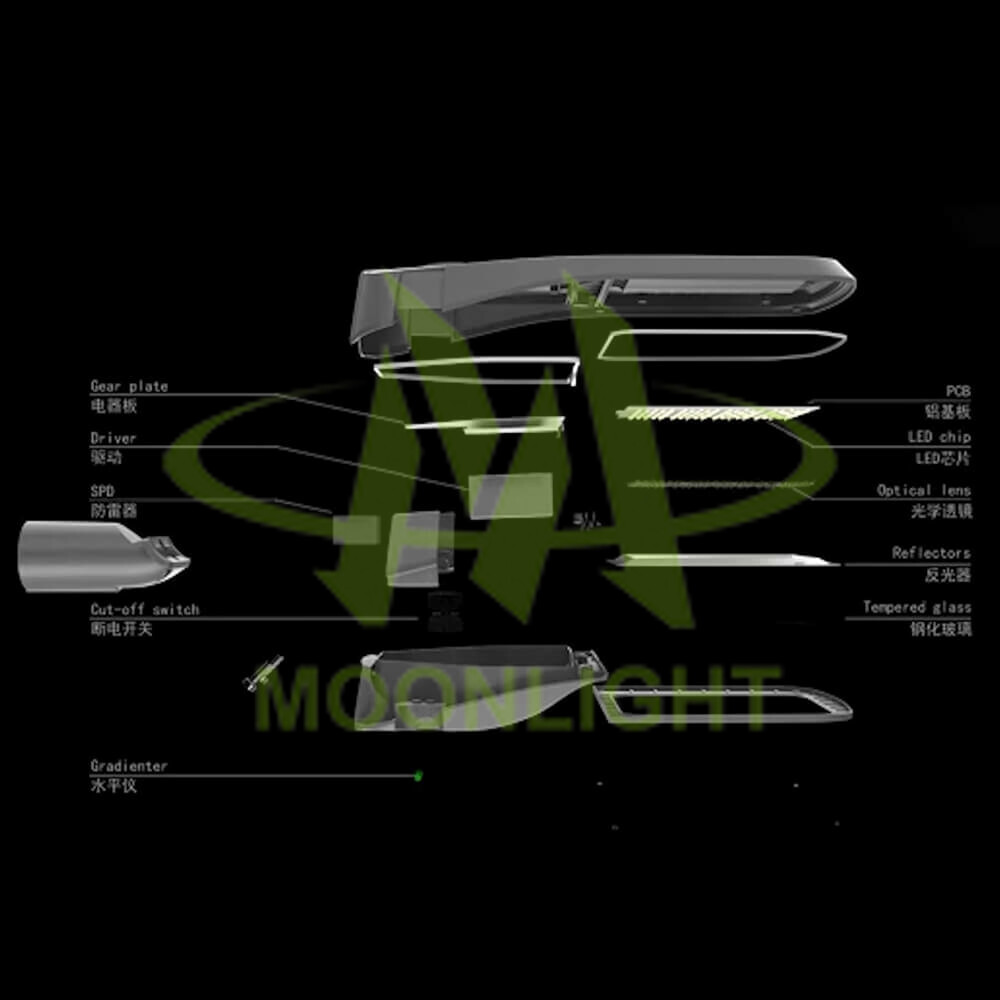

Moonlight has been committed to providing all kinds of led light housing and SKD(Semi Knock Down)service for LED street light, LED floodlight, LED wall pack, LED high bay and relative accessories since 2011.For more information, call +86-571-28173205, email [email protected], or follow us on LinkedIn, Facebook and Twitter @ledlighthousing