With Moonlight effective die casting, you can produce thousands of high-quality molded casts in a relatively short amount of time. Highly economical, cost-effective, uniform quality and high degrees of accuracy are original defined by die casting mold design and machining. The machining process of die-cast parts must be considered well before any order. Die-casting mold manufacturer and supplier Moonlight Team can carefully evaluate machining requirements. This can lead to near-net shape with few operations.

Moonlight Technology Mold Development Process

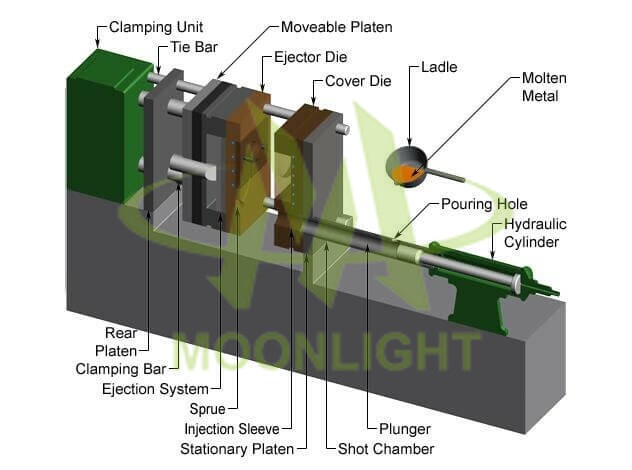

Die casting is an automated casting process in which liquid metal is pressed into a mold under extreme pressure at a high rate of speed. This casting process is highly suitable for mass production of components and is generally used with alloys that have a lower melting point. Since permanent metal molds are utilized for the die-casting mold process, it is possible to produce large and complex components with low wall thicknesses.

Moonlight Technology Die-casting Molds

The molds that are utilized within the die-casting mold design process are constructed from premium, heat-resistant steel grades. The molds are halved to form a cavity into which the liquid metal is pressed during the casting process. A die-casting mold is so strong, over a million parts can generally be created with a single mold. However, the actual life of the mold will solely depend on the die casting materials that are used.

Advantages of Moonlight Technology Die Casting Mold Development

Die casting utilizes non-ferrous metals (such as alloys of aluminum or zinc) to manufacture components. The chosen alloy for an application depends on budget, weight, and material properties. Other benefits associated with the use of die-casting mold design, include:

- High thermal conductivity

- High electrical conductivity

- Good processing properties

- Very good EMI/RFI isolation

- High corrosion resistance

- High strength and hardness

Moonlight Technology Quality Die Casting Mold Design Benefits

When it comes to high quality die-casting mold development there are several influences that contribute to the overall success of the process. These factors include the following:

- First Class Engineering, die-cast tools design

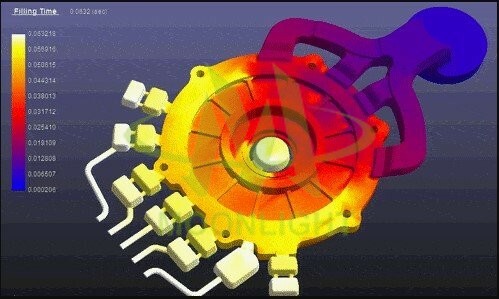

- Process parameters: gate size, location, feeding speed, fill time, pressure etc.

- Parting line, runner, overflows, venting, cooling.

- Minimum and Maximum wall thickness.

- Choice of the mold material and hardness based on mold forces calculation.

- Flow simulation.

- Draft, radii, filets.

- Machining accuracy.