LED Street Light Parts

LED Street Light Parts

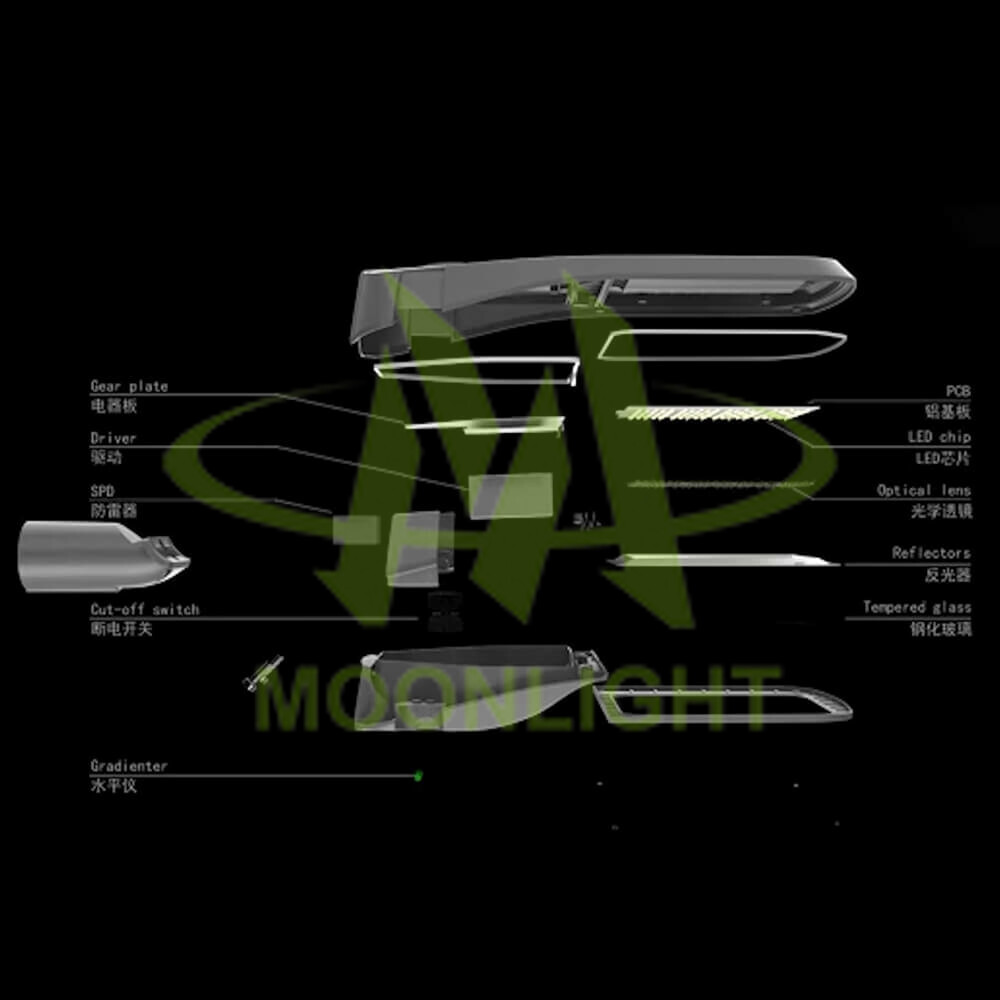

What is LED street light parts?

Different people may have different answers. As a LED street light housing supplier and manufacturer, we believe that LED street light components should include these components: aluminum alloy die-casting or extruded LED street light casing, PCBA, thermal paste, lens, reflector, LED driver, photocell, lamppost, cable.

1. What is LED street light housing?

LED road light housing is the casing of street light, which also named as LED street light housing, LED street light case, LED street light casing, LED street light enclosure, LED street light shell and LED street light body. It include the coated aluminum alloy die-casting or extruded parts, tempered glass, silicon gaskets, clips, screws, reflector. A good design and thick enough street light housings with nice coating can be used for 5-10 years, less maintenance and durable.

A. Die-casting or extruded aluminum alloy parts.

They are made from aluminum alloy with molds. After the treatment, they will be coated for anti-corrosion. Most LED street lamp casings are produced with die-casting molds for heavy-duty road lighting application. For LED street light housing, the surface of the aluminum substrate mounting area is very important for the thermal management. You can see many fins on the back of the street light casing, which are called heat sink of LED street light. In order to pass the test of impact rating, you will also find many strengthening rib in the LED street light shell. For a heavy-duty LED street light, the LED street light housing will be heavy and thick, so it can work for long lifespan.

B. Tempered glass.

Most of street light bodies are using 5mm tempered glass to enhance the mechanical strength, so they can pass the IK08, IK09 or IK10 impact rating test. Some of them even use 6mm tempered glass. Only a few of them will use 4mm tempered glass.

C. Silicon gaskets.

They are normally used for ingress protection. Most of our silicon gaskets are made by molding, so they can perfectly match the slots reserved on the die-casting parts of our street light shell. The light transmittance of the tempered glass is also very important. Normally the transmittance of the glass we are using is over 90%, so they can reduce the loss of light output.

D. Clips.

There are tool different types of clips. The most common one is for fixing the lid of the LED driver box of the street light case. Normally it could be SUS304 or coated die-casting parts. The other type is for fixing the tempered glass on the back of the frame. In order to prevent corrosion, most of the clips are made of SUS304 stainless steel or coated die-casting parts. Die-casting parts will make it look more beatiful, but SUS304 clips can use much longer.

E. Screws.

You may find many different specifications of screws or bolts when you unbox a LED street light. Normally all the screws we have used outer are SUS304 screws or bolts for anti-corrosion. Only the screws we have used inside of the LED street light are normal types for easily assembling with tools.

F. Reflector.

Except the lenses, some LED street light housings also have the reflector to make sure that the emitted light will not be blocked by the inside of the LED street lamp.

2. PCBA.

For LED street light, the PCB is the aluminum substrate. PCBA means printed circuit board +assembly. In fact, there are only LEDs and resistances on the aluminum substrate.

3. Thermal paste or thermal pad.

It is used to transfer the heat from the PCB to the bottom of the LED street light body. Sometimes customers also like to use adhesive thermal pad. Normally the thermal paste will be cheaper than thermal pad. If you want to use thermal paste, make sure you have prepared a stencil based on the PCB (aluminum substrate), so the thermal grease can be evenly coated. If you use a thermal pad, make sure to choose the high thermal conductivity type. Normally the thermal pad supplier will cut them into the pieces as your need.

4. lens.

Normally the lenses are made from two types of materials: Acrylic and PC. If the LED street light cabinet you plan to use didn’t have a tempered glass cover, make sure to choose the lens made from PC. Because PC have better performance for anti-UV. If there is a tempered glass cover on the LED street light casing, you can choose the acrylic type. Normally the acrylic lens has better light transmittance. One more thing, the PC lens can be used under 110 degree, and the acrylic lens can be used under 80 degree.

5. Reflector.

In order to prevent the light blocked by the LED street light casing, some LED street light housing manufacturer will also provide the reflector with the LED street light casing kits. Normally the reflector is made from aluminum alloy or ABS.

6. LED driver.

LED driver is very important for the lifespan of LED street light. If you plan to provide a long time warranty for your LED street light, please remember to choose the brand with good reputation, like Mean Well, Philips, Osram, etc. Generally, the life span of LED drivers is much shorter than that of LEDs. If you choose a bad quality LED driver, you have to spend much money on the cost of maintenance.

7. Photocell.

Photocell are normally used to control the LED street light turn on and off, which is optional for the road lighting application.

8. Lamppost.

The Lamppost is used to fix the LED street light at the side of the road. It has different material and different quality.

9. Cable.

If the cable of the driver is not long enough, you also need to prepare some cable to connect the driver with the power supply.

From the following video, you can more intuitively feel how LED street light parts are combined into a LED street light:

This article is based on our working experience of LED street light housings and LED road lighting applications. We own the copyright of this article, please indicate the source for reprinting. Thank you!